Ferro Silicon Powder For Steelmaking minerals metallurgy

Use

(1) ferrosilicon powder is an important metallurgical raw material, widely used in casting, steel manufacturing, aluminum alloy manufacturing and other fields. Ferrosilicon powder can be used as a reducing agent to reduce oxides in metallurgical furnaces, thereby obtaining pure metals.

(2) ferrosilicon powder can also be used to prepare various casting alloys. In steel manufacturing, ferrosilicon powder can be used as a desulfurizer to remove sulfide in steel, thereby improving the quality of steel. In the manufacture of aluminum alloys, ferrosilicon powder can be used as an additive to improve the strength and hardness of aluminum alloys.

(3) ferrosilicon powder is also widely used in chemical and electronic fields. In the chemical industry, ferrosilicon powder can be used to produce organosilicone compounds, siloxanes and silanes. In the field of electronics, ferrosilicon powder can be used to prepare semiconductor materials, solar cells and so on.

Characteristics and application of ferrosilicon powder

1. High purity and stability

Through the fine preparation process, ferrosilicon powder can achieve high purity requirements, thus ensuring its stability in a variety of applications. This high-purity ferrosilicon powder can provide a reliable material basis to meet the high material requirements of different industries.

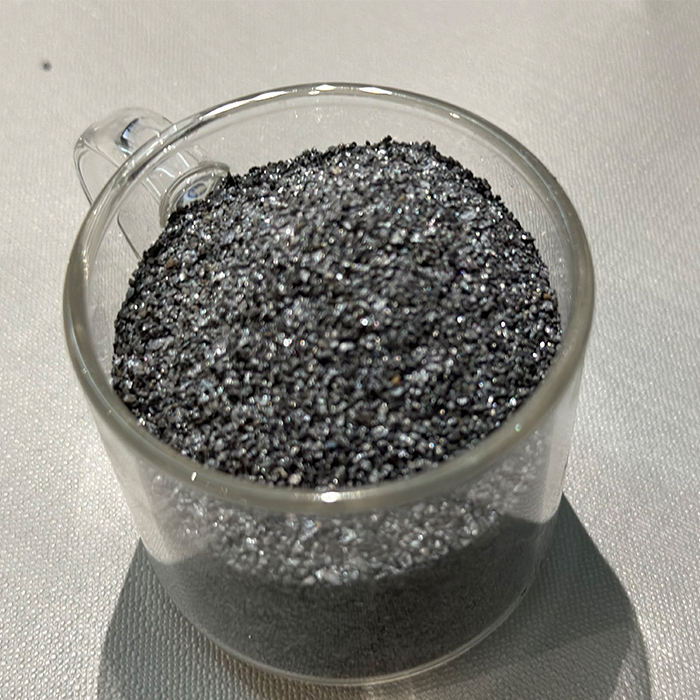

2. Uniform particle size with good fluidity

The particle size of ferrosilicon powder can be regulated according to specific needs, so as to meet the requirements of different industries for particle size. The uniform particle size and good fluidity make the ferrosilicon powder easy to mix and process in the production process, and improve the production efficiency.

3. Excellent magnetic permeability

Due to the excellent performance of ferrosilicon alloy in magnetic properties, ferrosilicon powder is widely used in electromagnetic equipment such as motors, transformers and inductors. The magnetic permeability of ferrosilicon powder can improve the efficiency and performance of electromagnetic equipment, improve energy utilization and reduce energy consumption.

4. Good wear resistance and corrosion resistance

Ferrosilicon powder can enhance the wear resistance of the material, thereby extending the service life of the equipment. At the same time, the corrosion resistance of ferrosilicon powder makes it still able to maintain good performance in harsh environments, and is suitable for various special conditions.

In addition to the above characteristics, ferrosilicon powder also has a low coefficient of thermal expansion and excellent conductivity. This allows the ferrosilicon powder to remain stable at high temperatures and to conduct heat efficiently. Therefore, ferrosilicon powder is widely used in the field of superalloy preparation and thermal management.

Chemical element

|

Item% |

Si |

P |

S |

C |

AI |

|

≤ |

|||||

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

0.5 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.1 |

0.1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.05 |

0.05 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.02 |

0.02 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

0.5 |

Notice:Production of different specifications of silicon calcium alloy according to customer requirements