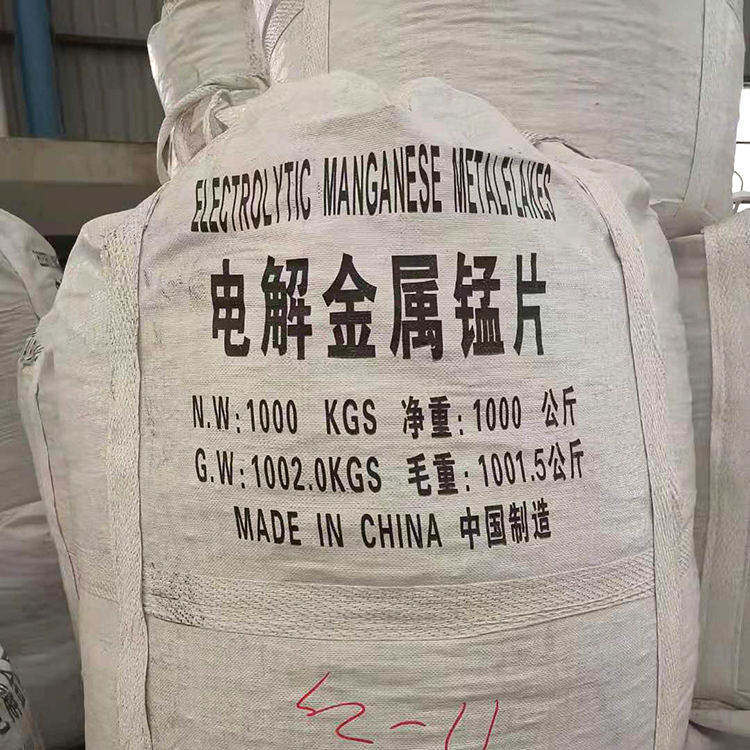

Manganese flake Electrolytic pure Mn with purity lumps 95% 97% metal

Application

The purity of manganese metal sheet is very high, its function is to increase the hardness of alloy metal materials, the most widely used are manganese-copper alloy, manganese-aluminum alloy, manganese can improve the strength, toughness, wear resistance and resistance of the alloy in these alloys corrosive. Application fields Manganese and manganese alloys are one of the indispensable and important raw materials in the iron and steel industry, aluminum alloy industry, magnetic material industry, and chemical industry. Manganese metal flakes are indispensable additives in the smelting industry. Manganese metal flakes processed into powder are the main raw materials for the production of manganese tetraoxide. The original magnetic materials widely used in the electronics industry are produced with manganese tetraoxide. Electronics industry, Both the metallurgical industry and the aerospace industry need manganese metal flakes. With the continuous development of science and technology and the continuous improvement of productivity, metal manganese flakes have been successfully and widely used in iron and steel smelting, nonferrous metallurgy, electronic technology, chemical industry, environmental protection, Food hygiene, welding rod industry, aerospace industry and other fields.

Ferro manganese can be divided into 3 categories according to the carbon content.

Low carbon:carbon is not more than 0.7%;

Medium carbon:carbon is from 0.7% to 2.0%;

High carbon:carbon is from 2.0% to 8.0%.

Chemical Element

|

Electrolytic Manganese Metal Flakes |

|||||||

|

Product Grades |

Chemical element | ||||||

|

Mn(%min) |

C(%max) |

S(%max) |

P(%max) |

Fe(%max) |

Si(%max) |

Se(%max) |

|

|

≥(Min) |

≤(Max) |

||||||

|

Mn99.9 |

99.93 |

0.01 |

0.02 |

0.0006 |

0.0022 |

0.0003 |

0.037 |

|

Mn99.8 |

99.8 |

0.02 |

0.03 |

0.005 |

0.03 |

0.005 |

0.06 |

|

Mn99.70 |

99.7 |

0.04 |

0.05 |

0.005 |

0.03 |

0.005 |

0.10 |

|

Electrolytic manganese metal |

|||||||

|

Model |

Mn(%min) |

C(%max) |

S(%max) |

P(%max) |

Fe(%max) |

Si(%max) |

Se(%max) |

|

Mn99.95 |

99.95 |

0.01 |

0.03 |

0.001 |

0.006 |

0.002 |

0.0003 |

|

Mn99.80 |

99.80 |

0.02 |

0.03 |

0.005 |

0.003 |

0.005 |

0.06 |

|

Mn99.70 |

99.70 |

0.04 |

0.05 |

0.005 |

0.003 |

0.010 |

0.10 |

|

Mn99.50 |

99.50 |

0.08 |

0.10 |

0.10 |

0.05 |

0.015 |

0.15 |