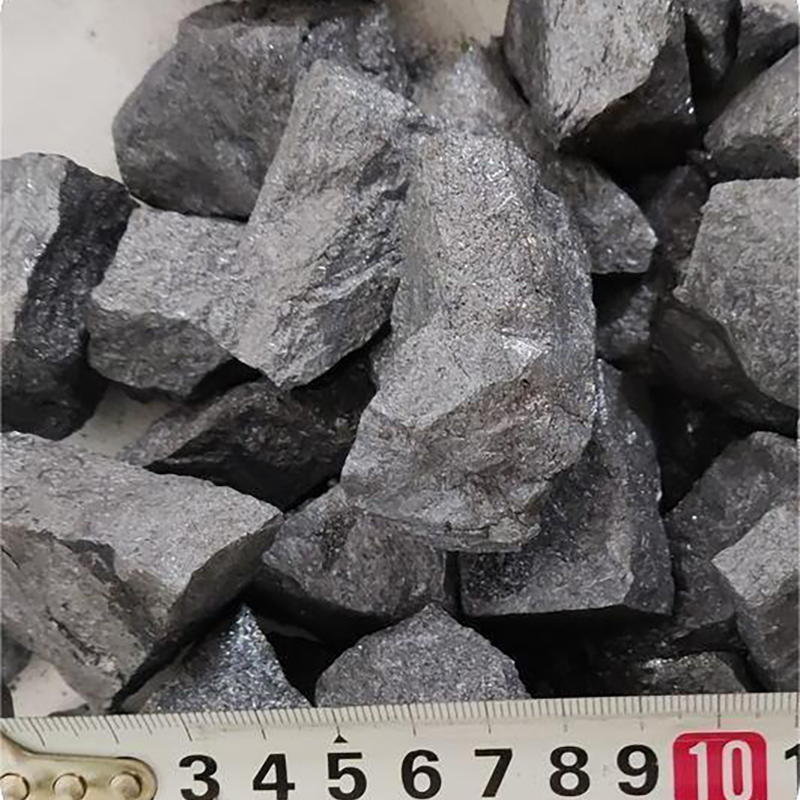

Ca Calcium Meta 1-3mm 2-6mm l Particles 98.5% Calcium Pellets Calcium Granules for Research

Application

The main mineral sources in industry are limestone, gypsum and so on.

Calcium can be used as alloy oil dehydrating agent, metallurgical reducing agent, deoxidizer, etc.,

Mainly used in industrial and medical fields.

Calcium is an essential macro element for the human body, and it is also the most abundant inorganic element in the human body.

It is also an activator of more than 200 enzymes in the human body, enabling various organs of the human body to function normally,

Insufficient or excessive calcium content in the human body will affect the growth, development and health of the human body.

Advantages of calcium metal

1. High-content silicon-calcium alloy is mainly produced in electrode furnaces a: It can produce silicon-calcium alloy of higher specifications. b: The product quality is stable, with less impurities. 2. Low- and medium-content silicon-calcium alloy is mainly produced in medium-frequency furnaces. a: It mainly produces silicon-calcium alloy of low and medium specifications. b: The output can be flexibly controlled with low production cost.

Chemical Composition

|

Ca |

CI |

N |

Mg |

Cu |

NI |

Mn |

AI |

|

98.5%min |

0.2%max |

0.1%max |

0.8%max |

0.02%max |

0.005%max |

0.03%max |

0.5%max |

|

98%min |

0.2%max |

0.1%max |

0.8%max |

0.02%max |

0.005%max |

0.03%max |

0.5%max |

|

97%min |

0.2%max |

0.1%max |

0.8%max |

0.02%max |

0.005%max |

0.03%max |

0.5%max |